Location, location, location. This familiar mantra of the real estate business also has a particular application for sulfur dioxide-emitting industries: seawater flue gas desulfurization (SWFGD). SWFGD systems offer pros and cons compared to conventional wet FGD systems.

FGD systems were developed in Europe in the 1930s. They were first installed on power plants in the United States in the 1970s to comply with environmental protection regulations. In 2019, approximately 250 coal-fired units at U.S. electric power plants had FGD systems, which accounted for about 52% of all coal-fired generators and 64% of all coal-fired electric generating capacity (approximately 144,000 megawatts (MW)). It should be noted, though, that the amount of U.S. FGD systems has been in steady decline over the past 10 years, mirroring the number of operating coal-fired power plants.

The FGD or SO2 scrubbing process typically uses calcium or sodium-based alkaline reagent. The reagent injects into the flue gas in a spray tower or directly into the duct. SO2 is absorbed, neutralized, and/or oxidized by the alkaline reagent into a solid compound, either calcium or sodium sulfate. The solid is removed from the waste gas stream using downstream equipment.

Scrubbers are classified as “once-through” or “regenerable,” based on how the solids generated by the process are handled. Once-through systems either dispose of the spent sorbent as waste or utilize it as a byproduct. Regenerable systems recycle the sorbent back into the system. At the present time, regenerable processes have higher costs than once-through processes; however, regenerable processes might be chosen if space or disposal options are limited and markets for byproducts (gypsum) are available.

Both types of systems, once-through and regenerable, can be further categorized as wet, dry, or semi-dry.

In a wet scrubber system, flue gas is ducted to a spray tower where an aqueous slurry of the sorbent is injected into the flue gas. Sulfur dioxide dissolves into the slurry droplets where it reacts with the alkaline particulates. The slurry falls to the bottom of the absorber where it is collected. Treated flue gas passes through a mist eliminator before exiting the absorber, removing any entrained slurry droplets. The absorber effluent is sent to a reaction tank where the SO2-alkali reaction is completed forming a neutral salt. In a regenerable system, the spent slurry is recycled back to the absorber. Once through systems dewater the spent slurry for disposal or use as a by-product.

A typical sorbent material is limestone or lime. Limestone is very inexpensive, but control efficiencies for limestone systems are limited to approximately 90%. Lime is easier to manage on-site and has control efficiencies up to 95% but is significantly more costly. Proprietary sorbents with reactivity-enhancing additives provide control efficiencies greater than 95% but are very costly. Electrical utilities store large volumes of limestone or lime on-site and prepare the sorbent for injection, but this is generally not cost-effective for smaller industrial applications.

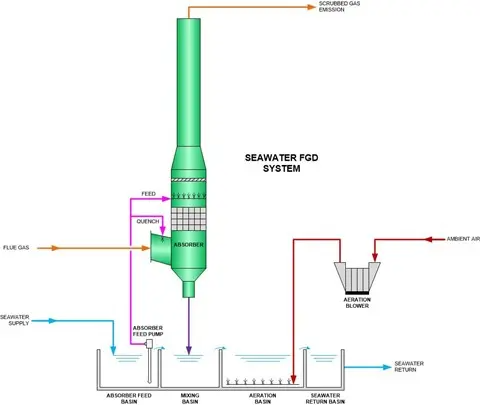

Wet FGD systems that use seawater as the sorbent solution are also available. In these systems, the limestone dissolves entirely in the seawater. The SO2 reacts with the sorbent liquid in a counterflow absorber. The sulfate produced remains in solution in the seawater and is discharged into the ocean. Generally, wastewater treatment is not required as sulfate salts are already present in seawater, and the increase in concentration is minimal. However, the high chloride concentration of seawater can result in corrosion problems. Hence, wet FGD systems using seawater must be constructed of corrosion-resistant materials that increase the capital costs.

However, this increase is minimal compared to overall more significant costs for conventional wet FGD units, which reflect the expenditures for reagent handling and by-product disposal facilities. In contrast, SWFGD units discharge their water by-product back into the sea and do not require as much capital investment. Additionally, SWFGD systems have much lower variable costs than conventional wet FGD units, but, again, they can only be installed in coastal areas.

So long as SO2-producing industries continue to operate, there will be a demand for FGD and SWFGD will only become more prevalent as the processes improve. However, it will always be limited by location, location, and location.