In most plants, steam generates at a single, high pressure, and where necessary, its pressure reduces. When pressure reduces, steam retains its high temperature. High-temperature steam requires components capable of withstanding those temperatures. In most cases, superheated steam is not required for reduced pressure applications. In these cases, a device called a desuperheater is used to reduce steam temperature to be at or near saturation conditions.

The word “desuperheat” means to extract heat from a superheated vapor to reduce its temperature. Desuperheaters reduce the temperature of a superheated vapor to a lower value, though not necessarily to the point of saturation.

There are two methods of desuperheating a vapor. One method uses a heat exchanger to extract heat from the vapor. A second method injects liquid, nominally water, directly into the superheated steam. Heat absorbed from the steam by the relatively cold water reduces steam temperature. This style of desuperheater is known as a “direct contact” type desuperheater since the two fluids come in direct contact to achieve the desuperheating.

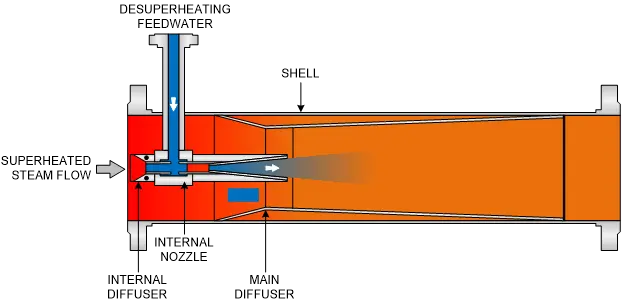

Refer to Figure 1. This steam desuperheater admits relatively cold water into the center of the high velocity, high pressure steam piping, which atomizes the water into tiny particles. Atomization increases the surface area of the water to enhance heat transfer. Heat in the steam is transferred to the atomized water, lowering steam temperature while raising the temperature of the water. Since the water entered the system near saturation temperature, heat absorbed from the steam is sufficient to flash the water to steam.

It is preferred to use hot water near the saturation temperature so that it is mainly the latent heat extracted to evaporate the injection water. This minimizes liquid water in the steam meaning the water cannot erode piping or settle out of the steam. To further minimize piping erosion, the main diffuser is typically a wear item, expected to need periodic replacement. Some direct contact desuperheaters like those made by Komax Systems use multiple spray nozzles to atomize water.

Figure 1 – Desuperheater Cross-Section

The advantages of these direct contact desuperheaters include increased response to automatic controls and lower initial cost. Most desuperheater applications require the ability to operate over a range of steam flows, a property known as turndown, and another advantage of direct contact desuperheaters. Turndown is the maximum to minimum flow ratio where accurate temperature control can be maintained. For example, if a desuperheater is designed to operate at a maximum flow of 50,000 lbs/hr, and a minimum flow of 5,000 lbs/hr, the turndown is 10:1. Turndown is a function of the line velocity in that the minimum controllable flow creates the lowest velocity capable of suspending water droplets until they are evaporated. This reduces erosion on downstream piping and components.

Despite being the only discussed in this article, direct contact desuperheaters are not the only methods to exist. The desired application depends on the user and the characteristics required of the desuperheated steam.