Zero Liquid Discharge (ZLD) is increasingly becoming a solution to wastewater management at power plants. Stricter environmental regulations, public perception, and water shortages are some of the concerns driving plants to the implementation of ZLD processes. In fact, water-stressed regions like India and China have become a proving ground for new and refined ZLD technologies and processes. In the US, California energy policy makes permitting of new installations difficult, if not impossible, without ZLD or dry cooling technologies.

ZLD is most often achieved through wastewater treatment systems, and creative solutions can also be reached. One example is provided by a coal-fired plant near Tampa, FL. This plant modified its existing wastewater treatment systems to provide for effluent reuse, rather than discharge. Additionally, the plant began reclaiming wastewater from nearby municipalities for makeup cooling water use. This creative approach provides a win-win outcome for all parties.

As each of the above factors – regulations, shortages, and perception – are sure to grow stronger in the future, ZLD projects will become that much more important. Planning for ZLD, now, can give plants a head start on future constraints.

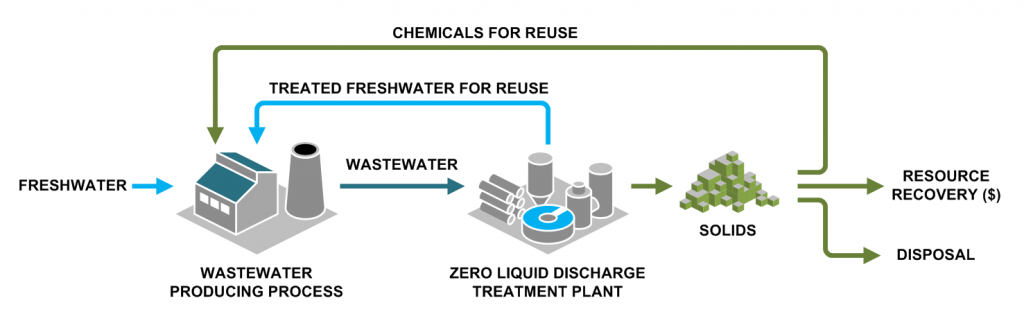

When implementing ZLD, plants assess all sources of water and wastewater as potential resources for the plant and look for treatments that allow for reuse by plant systems. Furthermore, the analysis of plant water sources and the wastewater produced is critical to designing a ZLD system that addresses the chemical, size, and recovery design factors. ZLD approaches will utilize any available treatment processes and technologies to that end. The illustration below shows the basic operation of a ZLD system.

The individual processing steps of conventional ZLD treatment plants include:

Water treated by a ZLD system can then be reused by plant processes. For example, wastewater treated and recovered at a Western, Pennsylvania power plant is reused by its Flue Gas Desulfurization (FGD) system. Effective ZLD systems consider all wastewater as a potential source for water reuse within the plant. In doing so, small streams from the various parts of ZLD system can add up to large returns on net water use.

Installation of a ZLD system typically involves substantial costs: capital investment in equipment, increased energy expenditures, and space considerations all add up. However, there are a number of factors that point to a positive economic outlook for ZLD.

First, operating costs of ZLD-related technologies/processes can often be offset by the sale of treatment byproducts. Gypsum recovered from FGD systems is a popular example. The recovered byproduct can be sold for drywall manufacturing. Other examples include calcium carbonate, critical metals and elements, and others can all result in additional revenue streams. Next, many private and public entities – such as the Water Reuse Foundation and the U.S. Bureau of Reclamation – are committing to research and development that aim to drive down ZLD costs. A recent example includes an analysis of electrodialysis (ED) technologies in the replacement of RO. In this study, ED proved to be both more effective with operating costs 20% below those of RO.

Finally, as mentioned before, future environmental regulation is likely to force ZLD solutions on industrial plants; ZLD systems may simply be the cost of doing business, anyway. It may not make economic sense to invest in ZLD today, but awareness of and preparation for ZLD installation in the near future is essential.