In this article, we will discuss waste heat. The process of burning fuel in a boiler to generate steam has many inefficiencies. The Rankine cycle itself is very inefficient, with numerous losses in each stage. Additionally, flue gas leaving the boiler contains a significant amount of thermal energy. This energy, if not properly harnessed, just dissipates into the environment.

Waste heat energy – energy that is generated in the combustion process which is not put into any practical use and is wasted and dumped into the environment is detrimental to overall plant performance. Recovering the waste heat can be conducted through various waste heat recovery technologies to provide valuable energy sources and reduce the overall energy consumption.

Rankine cycle plants have several different ways to use this energy. One common way to recover some heat is to pass the flue gas through a heat exchanger. It is then used to heat the feedwater before the water is fed to the boiler. These heat exchangers are commonly known as ECONOMIZERS or FEEDWATER HEATERS. Raising the temperature of the feedwater using an economizer improves plant efficiency by lowering the amount of energy that must be added to the boiler by combustion.

A second common heat recovery mechanism used is to pass the flue gas through a heat exchanger, where it is used to pre-heat the incoming combustion air before the air is provided to the furnace. These heat exchangers are commonly known as AIR PREHEATERS. Air Preheaters improve overall boiler efficiency by transferring heat from the flue gas to the incoming air used for combustion and coal drying.

Both the economizers and air preheaters can have a significant impact on plant efficiency. This directly results in lower fuel consumption, lower carbon dioxide (CO2) emissions, and improved power plant economics.

The waste energy in the flue gas can also be used for a variety of other processes. The process which will be explored here uses waste energy to evaporate wastewater; the evaporated wastewater (water vapor) is then released to the environment.

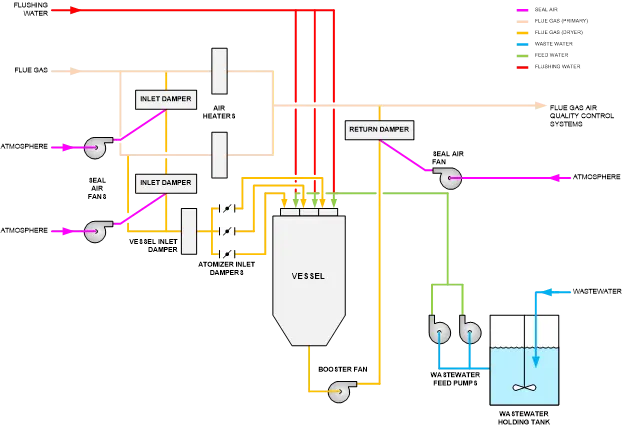

Figure 1 below shows a simplified overview of the process used in this application. A portion of the flue gas leaving the boiler economizer(s) is diverted to the evaporation system using a set of dampers. The remaining flue gas is directed as normal to the boiler air preheaters, and then to the air quality control systems.

The flue gas diverted to the evaporation system is introduced into a drying vessel. In the vessel, the heat in the flue gas is transferred to the wastewater, which evaporates the wastewater. The evaporated wastewater (steam) and flue gas mixture then return to the primary flue gas header.

The wastewater itself is introduced into the drying vessel using a sprayer (atomizer) to create a fine mist of water. This maximizes the surface area of the water, allowing for improved heat transfer between the wastewater and the flue gas.

Wastewater quality; specifically, Total Solids concentration, must be carefully controlled. The use of a Wastewater Holding Tank or other processes can help to minimize Total Suspended Solids. This is important because any suspended solids in the wastewater entering the spray nozzles could cause the nozzles to become plugged. This would result in improper atomization of the water.

The concentration of Total Dissolved Solids is equally important. Through the evaporation process, any dissolved solids in the wastewater do not evaporate; they precipitate out on the spray nozzles or in the evaporating vessel. The Total Dissolved Solids concentration of the water must be reduced before evaporation, or a system must be put in place to remove the precipitated solid materials.

In both cases, fouling of the spray nozzles can result in a reduction of the ability to transfer heat from the flue gas to the wastewater, and incomplete evaporation of the water introduced into the evaporating vessel.

The ratio of flue gas to wastewater introduced into the vessel must also be carefully controlled. If too much flue gas is introduced into the vessel for a given amount of wastewater, the temperature of the gas/steam mixture exiting the vessel and re-joining the flue gas header will be high. This could be detrimental to the downstream air quality control systems. If not enough flue gas is introduced, the wastewater will not be evaporated completely. The remaining water in the vessel could cause damage to the booster fan and other components in the system. In the system shown in Figure 1, both the flow of flue gas and the flow of wastewater are controlled and matched to ensure that the correct ratio is maintained.

The maximum flue gas flows into the vessel, or rather, the maximum amount of flue gas that can be diverted away from the air preheaters is another important consideration. Because some of the flue gas is being used by the evaporating system, less flue gas is flowing to the air preheaters; this could result in lower air temperature leaving the preheaters. This could be of concern, particularly during cold temperatures where the air temperature is critical to maintaining boiler efficiency.

Recovering waste heat energy can be conducted through numerous heat recovery technologies. Recovery of this energy is critical to reducing the overall energy consumption in the plant and improving efficiency. What heat recovery technologies are used in your plant?