The control of unit efficiency in a power plant requires a team effort from operators, maintenance personnel, engineers, and the support of plant management. The focus on plant efficiency is generally on the heat energy that is supplied to the plant as compared to the electrical energy produced, measured using a parameter called heat rate.

Often power plant personnel have difficulty in understanding how somewhat abstract ideas like heat rate are related to competitiveness and job security. The best way to understand the connection is to relate power plant heat rate to a dollar value based on fuel cost. The following simple calculation shows the effect of an improvement of 100 BTU/kWH for a hypothetical unit. The following parameters define the plant and the problem:

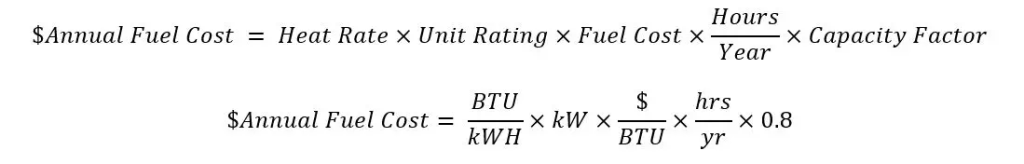

The following equation is used to calculate the total fuel cost for the operation of the unit for one year:

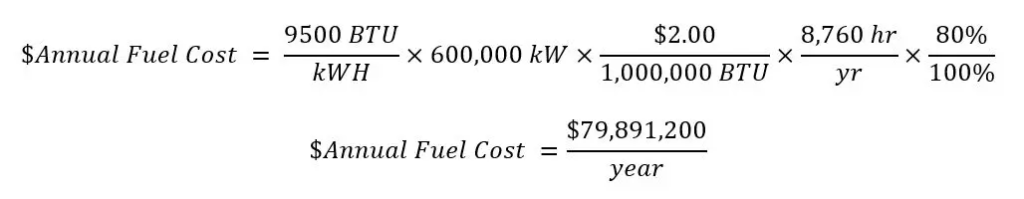

Substituting the values for the example unit into this equation for the base heat rate of 9,500 BTU/kWH, the following results:

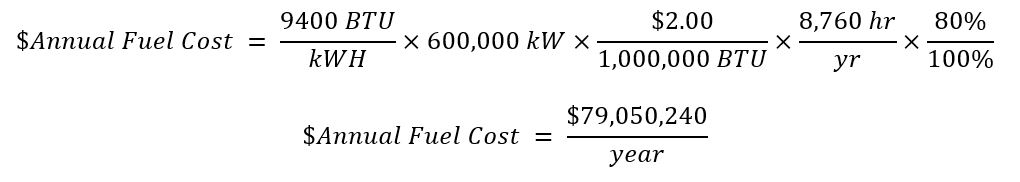

Substituting the values for the example unit into this equation for the improved heat rate of 9,400 BTU/kWH, the following results:

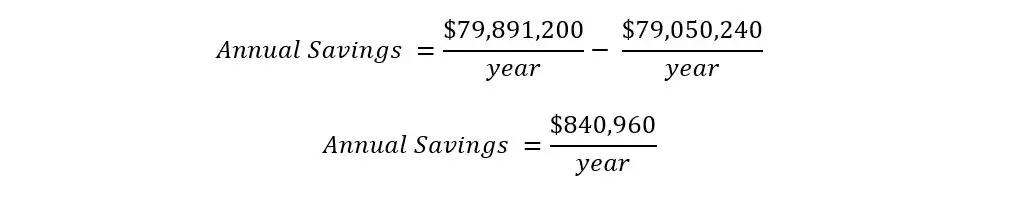

The savings due to the improvement in heat rate can be determined by calculating the difference between these two annual costs as shown below:

This calculation shows that a change in heat rate of 100 BTU/kWH for a unit with a 9,500 BTU/kWH (a little more than 1%) results in savings of almost $850,000! Power plant operators, maintenance personnel, engineers, and the support of the plant management should continuously strive to improve heat rate, and corresponding efficiency, for their units.

This blog is Part 1 of a three-part series. In the upcoming blog posts (Part 2 & 3), the following will be addressed: