In producing steel from iron ore and/or scrap, impurities such as nitrogen, silicon, phosphorus, sulfur, and excess carbon are removed from the raw iron ore. This molten “pig iron” is then converted to steel by alloying elements such as manganese, nickel, chromium, carbon, and vanadium. Different alloying agents and varying ratios are used to produce different steel grades based on customer needs.

Regardless of the grade of steel produced, pig iron is the largest constituent of steel, and as such, pig iron is a vital asset to the steel industry. Transporting molten pig iron from one facility to another is almost impossible due to the extreme temperature requirements needed to maintain the pig iron in a liquid state. However, if the pig iron is cast into ingots, those ingots can easily be transported for use in other facilities.

The conversion of molten pig iron to ingots can be accomplished in a pig casting machine. In a typical pig casting machine, molten iron is poured into a traveling series of ingot molds. The iron is cooled, and the solidified ingots are collected for transport.

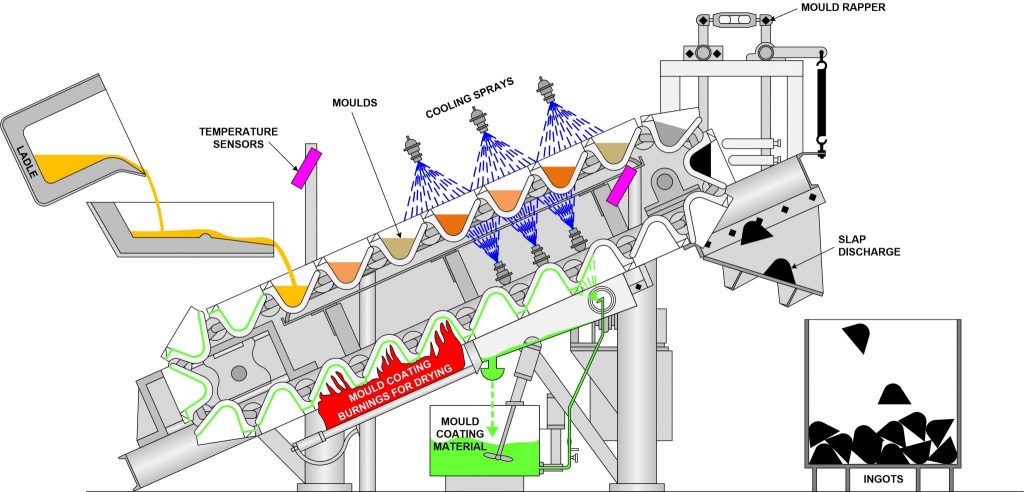

The figure below shows a diagram of a basic pig casting machine. There are several critical processes involved in the casting process.

Molten iron is transported to the casting machine and is carefully poured from the transportation vessel into discreet molds. These molds then begin traveling up the machine, where they are cooled and collected.

Once the molten iron has been poured into the molds, the iron must be cooled and solidified prior to discharge from the machine. To accomplish this, cooling water is sprayed both directly on top of the iron and on the underside of the mold. Water from this process can be collected and recycled; steam produced can also be captured and recycled.

Once the iron has solidified in the molds and reaches the top of the casting machine, the ingots fall from the machine into a collection bin. To assist in the release of the ingots from the mold, mechanical force may be applied to shake the ingots loose. The ingots collected in the bin are periodically removed for storage and transport.

To avoid damage to the mold and to prevent the iron ingots from sticking to the mold, a special mold coating is sprayed onto the mold surfaces, coating them in a protective film.

Prior to liquid iron filling the molds, the protective coating is dried. This prevents molten iron from coming into contact with water in the mold; it also serves to pre-heat the mold to minimize the thermal shock that occurs when the molten iron is first poured. This drying process is initially performed using gas burners; once casting operations are established, the residual heat remaining in the molds may be sufficient to dry the mold coating. At the U.S. Steel Gary Works facility in Gary, Indiana, a new casting machine is being installed, which will allow the Gary Works facility to supply pig iron to the U.S. Steel Big River Steel Works, located in northeast Arkansas.

Read more about this important project here.