Greenhouse gases and global warming have, over time, become accepted as the reason for Climate Change. Environmental scientists have concluded that greenhouse gases (GHG) are a major contributor to global warming. Fossil Fuels are so popular because of their low cost, availability, existing reliable technology for energy production, and energy density. They fossil fuels currently supply over 85% of the energy needs of the United States. This percentage is similar on a global scale1. Unfortunately, CO2 is a significant contributor to greenhouse gases. However, it is becoming a possible economic resource for the industry and energy production sectors.

In the first part of this blog, we looked at different methods of the capture of CO2 post-combustion, including Amine Based CO2 Capture, Carbonate Conversion, Membranes, and Enzyme Based Systems. This blog will continue the discussion to include Chemical Looping Technology and the Advanced Zero Emissions Power Plant.

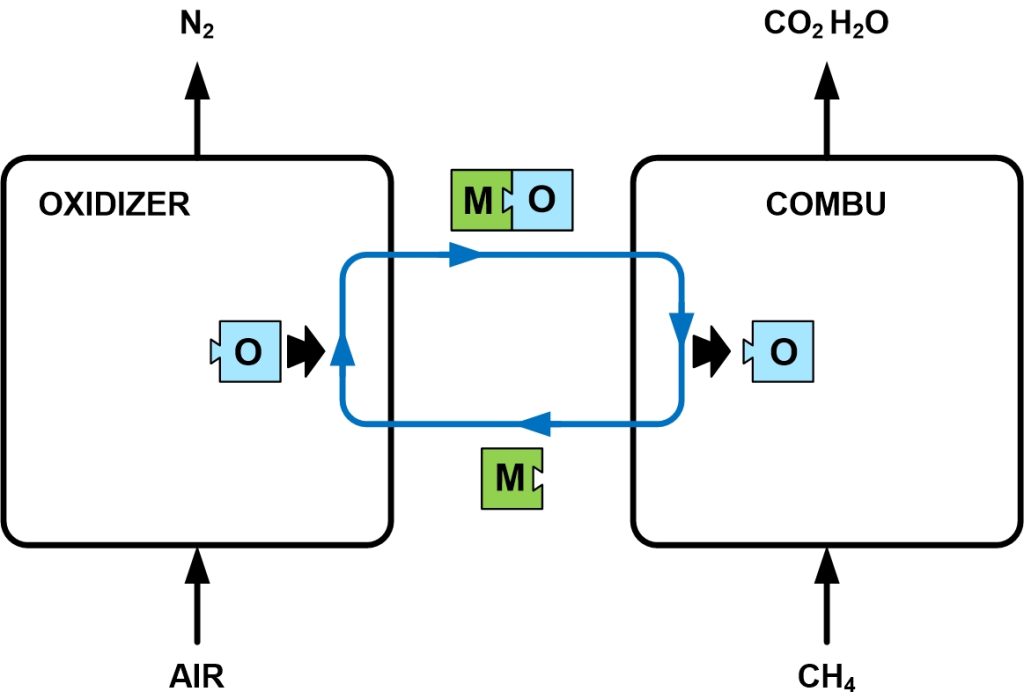

In a chemical looping system, the metal oxide is used to transfer O2 extracted from the air. It then feeds it back into the fuel for combustion. This has an added benefit in that the captured O2 provides the air needed for the combustion of the fuel, therefore, no NOx is generated and some of the power loss associated with the separation of the O2 from the air is mitigated. With this type of chemical looping system, even though CO2 is still produced, it is a much cleaner output of only CO2 and water, making it much easier to remove the CO2 from the flue gas2. See the figure below:

OXIDATION: exothermic

M + ½ O2 → MO

REDUCTION: endothermic

CH4 + 4MO → CO2 + 2H2O + 4M

M = Metal, MO = Metal Oxide

Many other methods to remove the flue gas would be extremely efficient in removing the CO2 if it were the only gas present in the flue gas. Other technologies that could be used for CO2 sequestration include sending the CO2 stream to industries that use the gas, such as farming of vegetables and other plants in a greenhouse situation. This would also allow the use of the waste heat generated by the power plant to heat the greenhouses as necessary.

Integrating greenhouses with CO2 capture has the added benefit of another revenue stream for the power industry. This may be even greater than power generation.

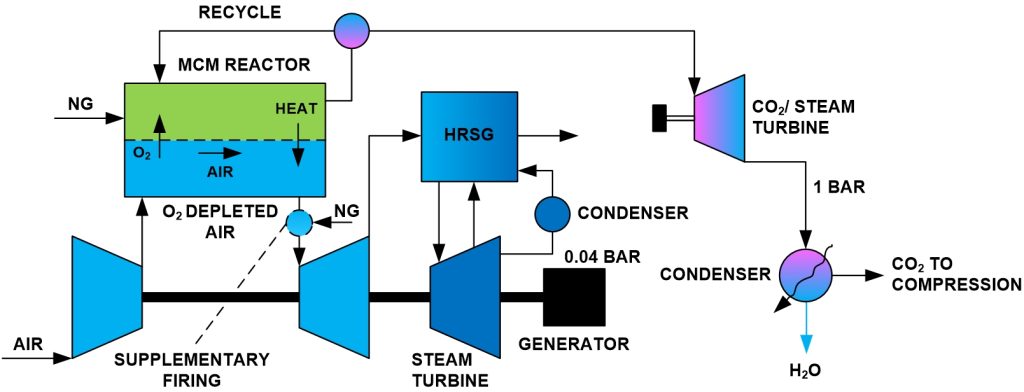

The Advanced Zero-Emission Plant (AZEP) is an oxyfuel cycle using methane or natural gas that essentially replaces the traditional combustor with an Ion Transport Membrane (ITM) reactor, resulting in a much smaller penalty for the separation processes of O2 from air, or CO2 from exhaust compared with conventional carbon capture technologies4. The AZEP uses a Brayton cycle combined with a bottoming steam cycle in addition to either an unconventional CO2, steam-like turbine, or a heat recovery steam generator that utilizes the availability of the combustion products exiting the ITM reactor. In this cycle, see the figure below, the pressurized air and natural gas enter the ITM reactor separately in addition to a portion of the exhaust gases from the turbine.

The AZEP cycle offers many advantages and directly implements the ITM technology for air separation and oxidation of the fuel. One of the strongest features of this cycle is the opportunity to use the conventional power plant equipment for the turbines and compressors. This avoids additional costs already incurred by using the ITM reactor.

In the next blog we will look at Pre-Combustion CO2 capture.