A report published by Senseye shed light on the consequences of improper equipment maintenance. Large industrial and manufacturing facilities lose an average of 323 production hours annually due to unplanned downtime (Automation.com, 2021). This downtime may lead to millions of dollars of lost revenue depending on cost.

One of the main contributors to unplanned downtime is improper machinery alignment. There are multiple consequences of misaligned equipment (Luedeking, 2008):

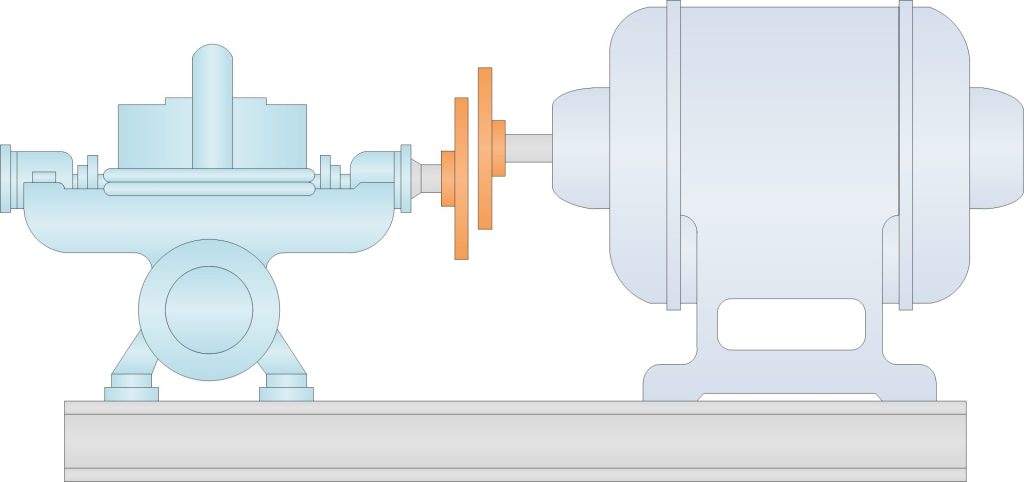

Machinery alignment is an essential practice in industrial facilities. When misaligned, rotating equipment (pumps, turbines, compressors) will not operate efficiently. Increased wear will require corrective maintenance. Instead of performing preventive maintenance as scheduled, premature outages will occur to correct issues.

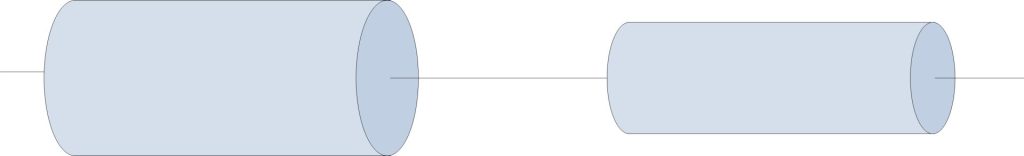

Two coupled shafts are considered to be perfectly aligned when their centerlines are on the same straight line (coaxial) at operating conditions.

Perfect alignment is not realistically obtainable as many forces are occurring during operation that will cause slight misalignment. It is important, however, to align equipment within the tolerances specified by the equipment manufacturer.

Operating conditions can cause properly aligned equipment to become out of tolerance during operation. The following is a list of factors that can affect the alignment of a piece of equipment:

Performing regular equipment inspections and checking for these conditions will minimize the resulting wear.

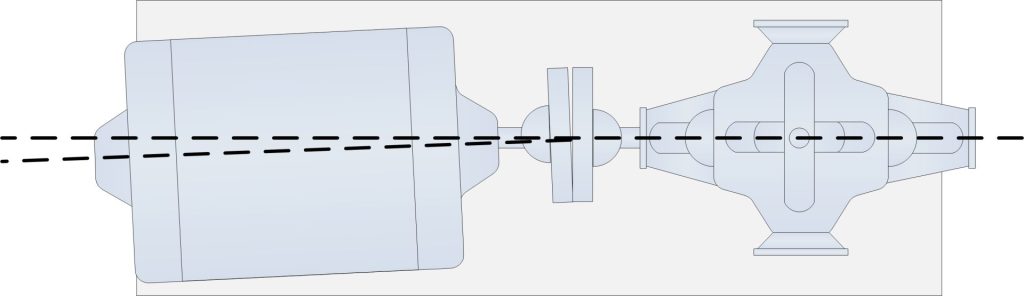

Misalignment falls into two categories, angular and parallel. Typically, equipment will experience a combination of both angular and parallel misalignment. Both types of misalignments can occur in the horizontal plane, vertical plane, or both. Angular misalignment occurs when the equipment centerlines cross.

Parallel misalignment exists when the centerlines of the two shafts are parallel but not concentric; that is the centerlines do not lie in the same line (plane).

The techniques and methods of checking alignment vary for each piece of equipment depending on installation and the type of coupling used. However, there are standard checks performed that minimize the chance of misalignment during operation. In general, perform the following checks before aligning and coupling equipment:

Understanding the importance of machinery alignment is not enough to ensure all the equipment at your facility runs smoothly. Maintenance procedures and qualification and training programs must be in place. Defining the skills and knowledge for each plant job creates a pathway to success. Providing employees with training and qualification milestones creates a highly proficient workforce. Expert craftsmen armed with detailed and accurate procedures are the surest way to keep equipment running.

Automation.com. (June 30, 2021). World’s largest manufacturers lose almost $1 trillion a year to machine failures. ISA. https://www.automation.com/en-us/articles/june-2021/world-largest-manufacturers-lose-almost-1-trillion

Luedeking, A. (July 1, 2008). Why alignment? Power Engineering. https://www.power-eng.com/news/why-alignment/