Proper lubrication is essential to keeping industrial equipment operating. Almost every machine and tool requires lubrication to protect its moving parts and ensure smooth operation. Every maintenance technician should have a strong working knowledge of lubrication principles and procedures to diagnose or better yet, to prevent equipment failures.

An article by Duke Electric revealed that over half of industrial motor failures are due to failed bearings, with 80% of bearing failures being caused by improper lubrication. While not every machine is driven by an electric motor, these statistics reveal that equipment lubrication is improperly performed on a wide scale.

Lubricants perform the following functions:

Reducing work and wear and removing heat are the result of minimizing friction. Resistance (in the form of friction) results in more energy required to create motion or to do work. A major role of lubricants is reducing the energy needed to cause that motion. Without lubrication, the energy from work is converted to heat between the two surfaces, which can result in damage.

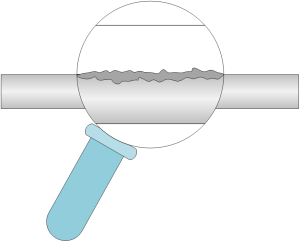

The machined surfaces of industrial equipment appear smooth to the naked eye. However, this is misleading. Machined surfaces contain peaks and valleys that will wear away without proper lubrication. In general, increased wear increases friction, resulting in more heat.

Excessive wear on a machine shaft causes imbalance. This can cause the shaft to become out-of-round. An imbalanced shaft increases the wear rate and creates additional problems with the machine. In extreme scenarios, improper lubrication of rotating equipment creates enough heat to melt (wipe) the bearing material and seize (weld) the equipment shaft to the bearing housing.

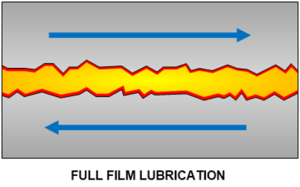

Separating the machine surfaces with a proper lubricant reduces friction in the machine. The lubricant layer equally distributes load between the high and low points of the surfaces. In a typical journal bearing, the lubricant layer is as little as 2 to 100 microns thick. The lubricant used must have the proper viscosity and contain the correct additives for the operating conditions. If the lubricant viscosity is too high, friction generated between the lubricant molecules will generate excessive heat. Conversely, too low of a viscosity will reduce the thickness of the lubricant layer, creating the potential for metal-to-metal contact.

With the importance of lubrication understood, the cause of improper lubrication must be investigated. Site personnel may develop the mindset that periodically adding grease to a motor or topping off a bearing with oil are effective lubrication methods. While the intention to maintain the equipment is good, the execution is poor.

The task of planning and performing maintenance at an industrial facility can be daunting. Additionally, building a qualification program for maintenance technicians with site-specific training can feel like an impossible undertaking. FCS is equipped and prepared to assist you with maintenance procedures and qualification and training programs.

Dukeelectric.com. (n.d.). Electric motor failure. Duke Electric. https://www.dukeelectric.com/motors/failure/guide/.

Machinerylubrication.com (n.d.). Lubrication regimes explained. Noria Corporation. https://www.machinerylubrication.com/Read/30741/lubrication-regimes

Wilson, C. (n.d.). 12 reasons why bearings fail. ReliablePlant. https://www.reliableplant.com/Read/30255/reasons-bearings-fail.