Bearings are among some of the more abundant and oftentimes small machine components in a plant. They are paramount to performance and efficiency as they reduce friction between adjacent moving parts.

Good bearing performance happens with smooth operation and minimal friction. In contrast, improper performance happens with rough and additional friction. This improper performance can lead to low efficiency, extra wear and tear on adjacent machine components, and ultimately bearing failure. The best method for avoiding bearing failure is to recognize signs and causes before the bearing fails. The three main causes of bearing failure are metal fatigue, misalignment, and improper lubrication.

There are four main methods for identifying bearing performance before complete failure:

Monitoring these conditions can give insight into potential problems and help avoid unnecessary interruptions due to abnormal bearing wear or bearing failure.

A bearing experiences a period called “Startup Time”, which varies with each piece of equipment. Startup Time is the time it takes to reach the normal operating temperature. After it reaches the normal operating temperature, it should remain at a relatively constant temperature. Operating temperatures may change due to shaft speed increases or for several normal/expected reasons. However, a sudden increase or decrease in operating temperature that cannot be explained could indicate a serious problem.

Operators must monitor temperature to determine if the normal operating temperature has suddenly increased or decreased. Checking the temperature occurs by checking the bearing housing rather than the actual bearings. This is used as a reference point since the actual bearings are encased in the housing and are not easily accessible.

Methods for monitoring bearing temperature:

A change in vibration is another method for identifying bearing performance. Vibration changes can be identified through touch or sensed through the floor. However, it is difficult to assess the importance of the change in vibration unless it is signification without the aid of special instruments.

Vibrations are monitored through:

Bearing noise is identified by plant personnel and requires no special equipment. Therefore, experienced personnel familiar with normal operations of a bearing should be able to hear an abnormal bearing noise that indicates it is beginning to fail.

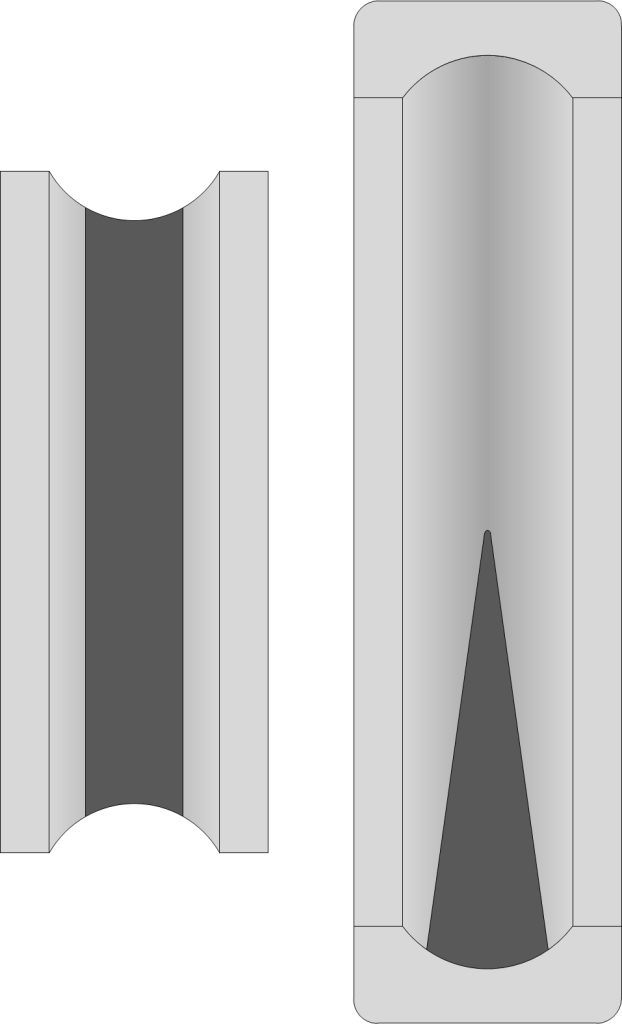

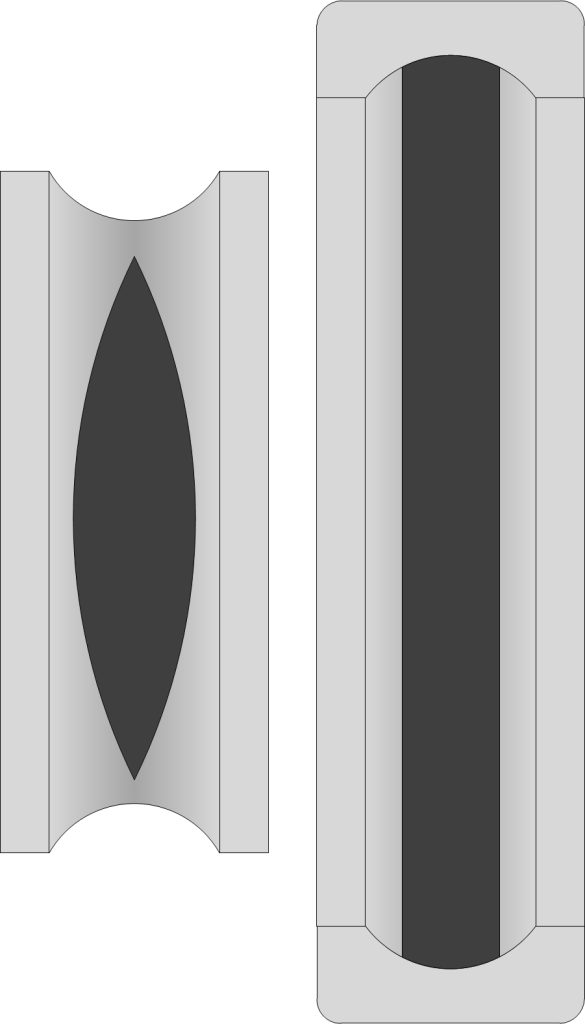

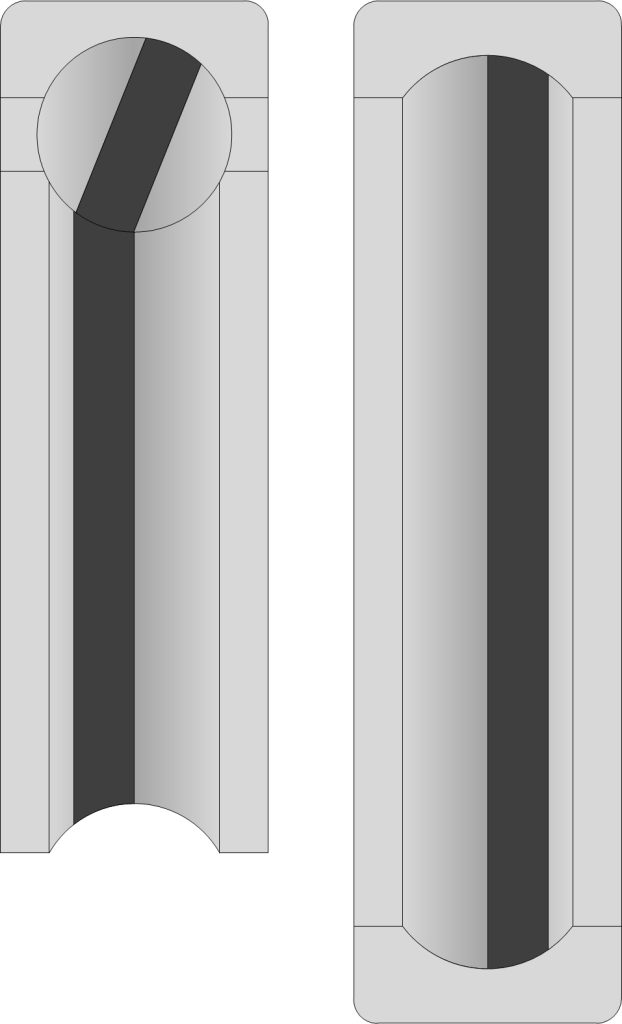

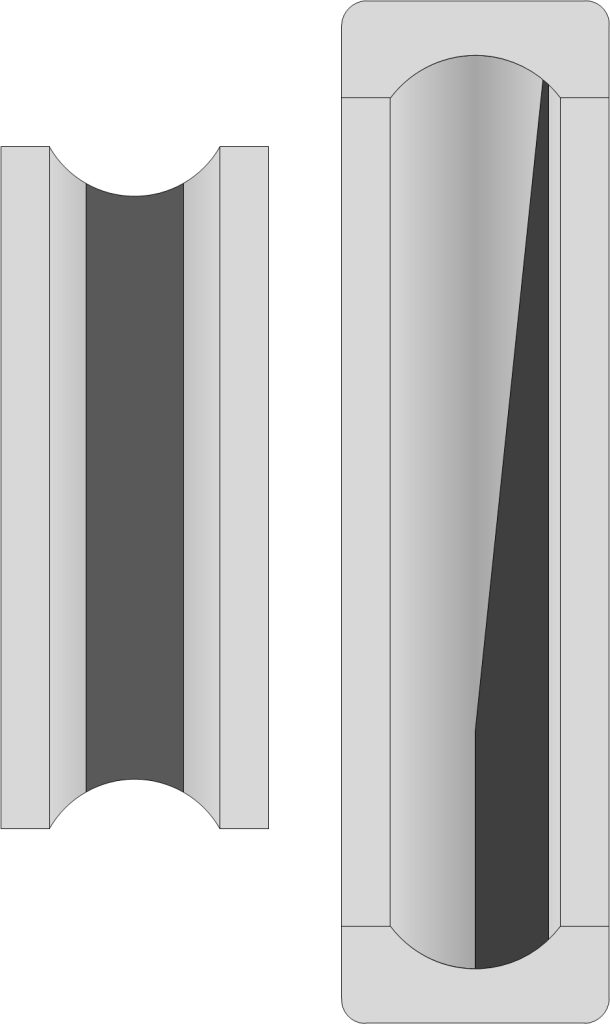

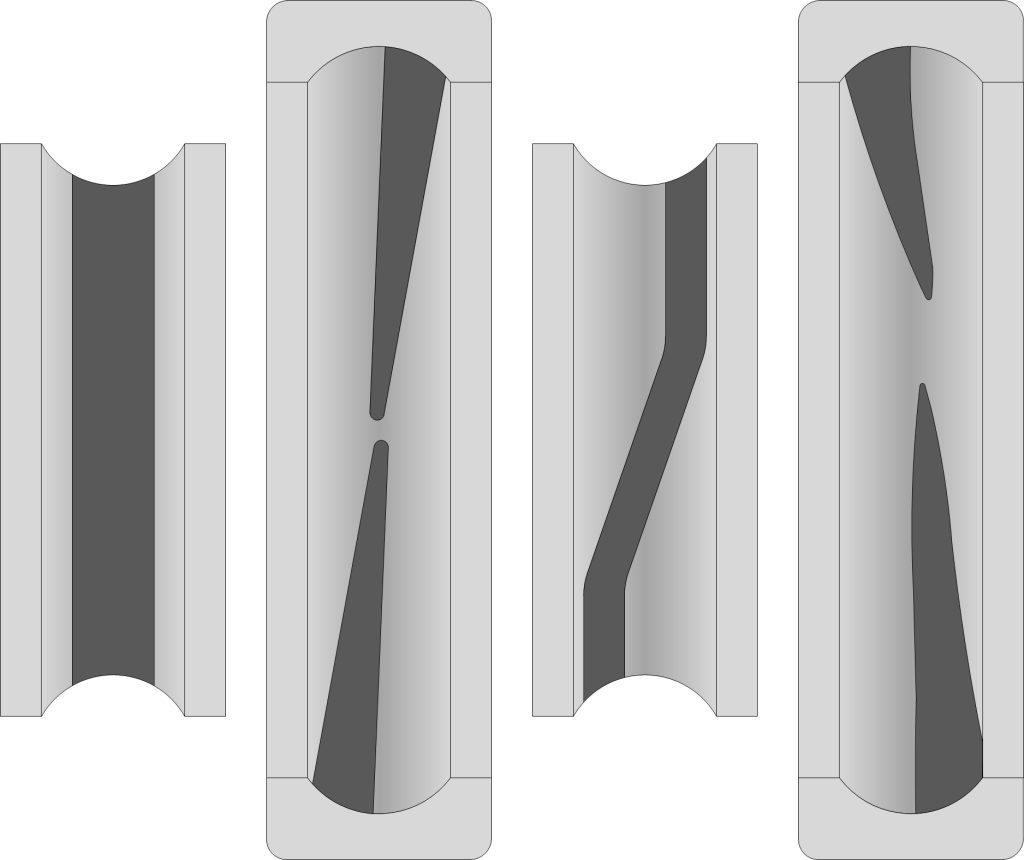

All bearings are expected to incur normal wear over time. However, some wear patterns indicate abnormal patterns that show issues that will ultimately lead to quicker bearing failure and lowered plant efficiency. Performance indications are found on the contact surfaces of the inner and outer races and on the rollers. Since wear patterns require disassembly to observe, they should be inspected and documented as part of component maintenance.

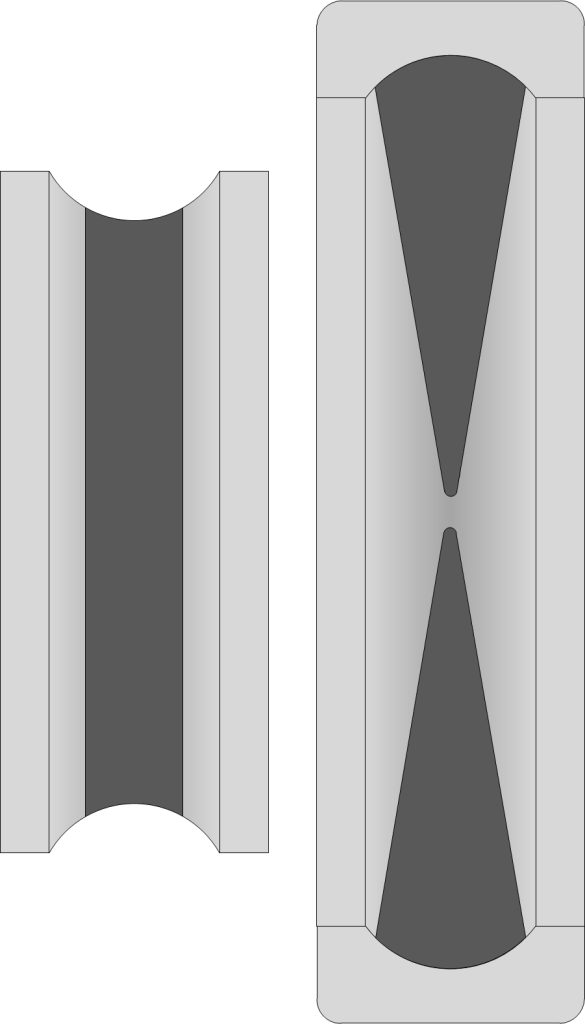

Normal wear patterns should appear on the inner and outer races.

Abnormal wear patterns indicate impending bearing failure and indicate issues such as metal fatigue, misalignment, improper installation, improper lubrication, improper contact, excessive vibration, and excessive loading. This wear can be seen in fine cracks, spalling, fretting, dents, and scratches.

Bearing performance, among other small machine components, can make or break the efficiency of the system’s ability to perform. Plant personnel should learn these methods and check on them with frequency depending on the criticality of the bearing. Identifying potential issues using these methods can prevent unnecessary shutdowns due to bearing failure as well as indicate issues with adjacent equipment that may cause bearing failure or lower plant efficiency.

Liquid Glass: The Characteristics of Laminar Flow