Combustion turbine performance changes with ambient air conditions. Ambient conditions are the dominant cause of changes from the design reference conditions. Combustion turbine performance is rated at standard conditions. These conditions include temperature barometric pressure and relative humidity. These reference conditions are 59°F, 14.7 psia, and 60% RH. Moreover, deviation from these standards affects combustion turbine performance.

The reference conditions make it possible to have a common reference to compare the guaranteed performance of different CTs. When a CT is bought, the reference conditions for that CT may be different because ambient conditions vary with geographic location.

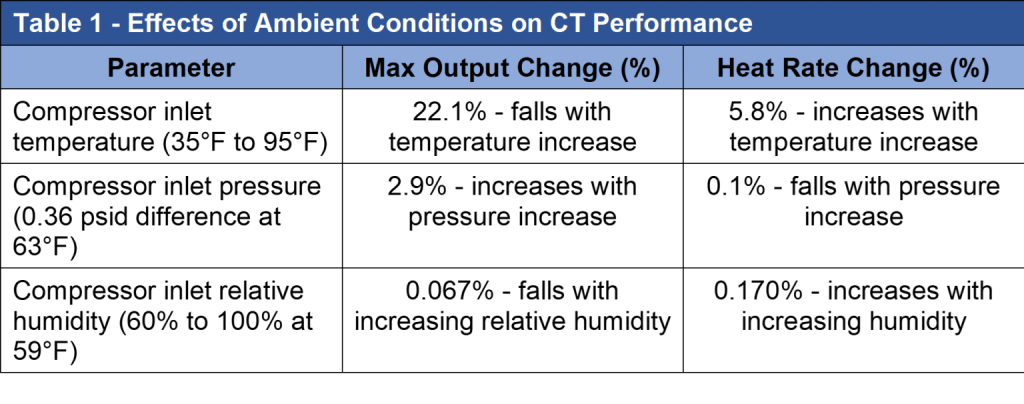

Combustion turbine performance changes as ambient air temperature changes. The graph below shows a CT with rated compressor inlet temperature (CIT) of 78.21°F, relative humidity 94%, and rated ambient pressure of 14.69 psia. This machine’s output falls 22.1% as the CIT increases from 35°F to 95°F. Also, heat rate increases (efficiency falls) by 5.8%.

The power and efficiency improvement with reduced air inlet temperature is because chilly air is denser as CIT falls. This means compressor air mass flow is greater. When more air is delivered to the combustion system, more fuel can be delivered. This results in greater energy input. Therefore, output increases. In addition, since fixed losses do not increase with the increased air and fuel input, efficiency increases.

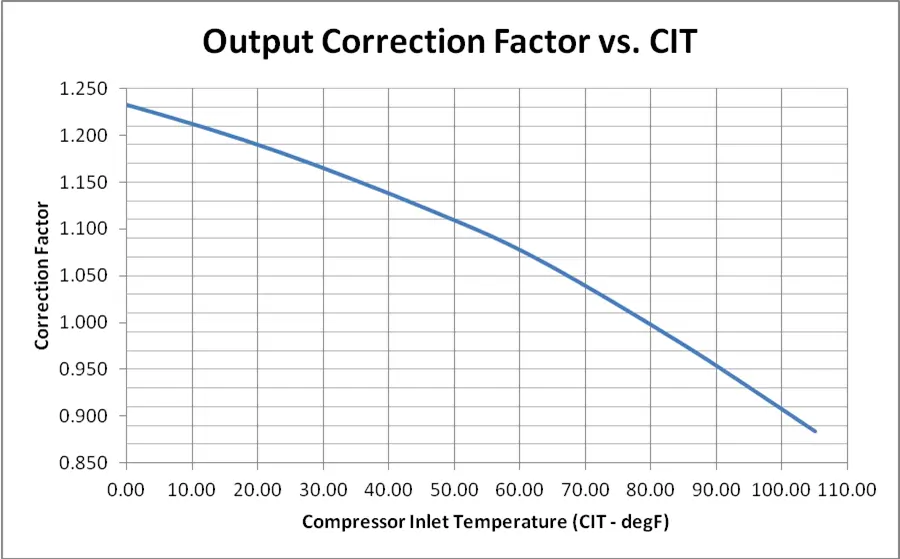

Normal atmospheric pressure at sea level is 14.69 psia. As elevation above sea level increases, atmospheric pressure decreases. As air density decreases, airflow and output decrease proportionately. There is no effect on heat rate. The graph below, “Compressor Inlet Pressure Correction Curves”, shows a standard altitude correction curve.

The CT elevation is obviously fixed. Still, there are variations in atmospheric pressure due to weather. Barometric pressure affects the output and efficiency of the CT. For example, the maximum barometric pressure seen at the example station was 14.93 psia and the lowest was 14.57 psia. This change in barometric pressure results in a 2.9% increase in maximum load. The heat rate decreases by 0.1% with this increase in pressure. Some combustion turbines have been designed to operate at very high altitudes.

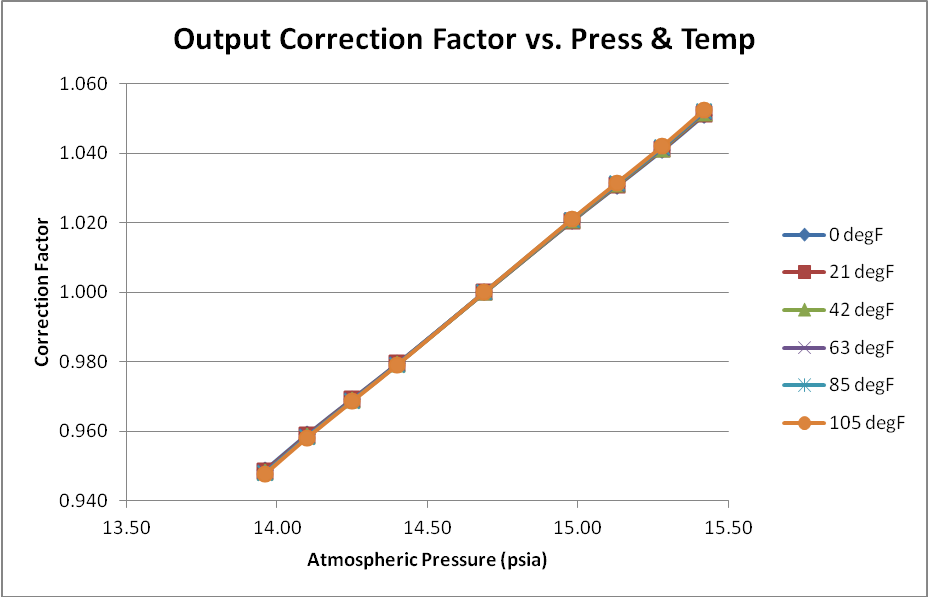

Humid air is less dense than dry air. Increased humidity causes a slight reduction in power output and efficiency. This is because of the lower molecular weight of the components of water vapor as compared to air (63% less). This results in decreasing mass flow through the compressor as humidity increases. Mass flow has a direct impact on power output, and thus efficiency. There is also a reduction in compressor efficiency as humidity increases.

The graph below shows the correction curve for the load as a function of specific humidity. Specific humidity is measured in pounds of moisture per pound of dry air. For a change from 60% to 100% relative humidity at 59°F, the specific humidity changes from 0.0064 lb water/lb dry air to 0.0110 lb water/lb dry air. Of course, relative humidity of 100% means that it is raining. With this change, there is a decrease in output of about 0.05%. Therefore, the heat rate increases (efficiency falls) by about 0.17%.

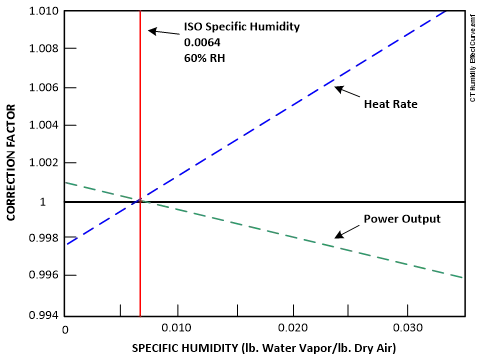

The table below shows the changes in maximum capacity (MW) and heat rate (efficiency) for temperature, pressure, and humidity for the normal variations discussed above. This table shows that compressor inlet temperature has the greatest impact by far on load and heat rate. In reading this table, recall that efficiency falls as heat rate increases.